At Watanabe Rubber, we are professionals in manufacturing rubber and plastic molded products.

At Watanabe Rubber, we are professionals in manufacturing rubber and plastic molded products.

With our experience in meeting a wide variety of customer requests from approximately 400 companies for over 40 years, we have acquired significant expertise.

We use our expertise to turn customers’ product concepts into reality, helping them to manufacture products that are steps ahead of their expectations.

If you have any problems, please allow us to help you solve them. At Watanabe Rubber, we are glad to offer our expertise based on over 40 years of experience.

WATANABE-RUBBER Co., Ltd

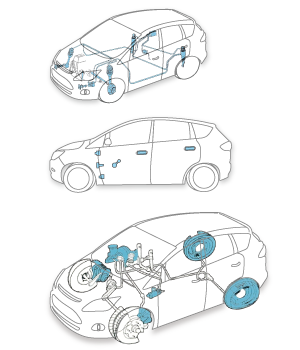

Product: Rubber parts for automobiles

Requests: Making improvements after the specifications are proposed

Our regular customer requested product improvements while maintaining quality and cost.

Improvements included:

1) Stabilizing product quality through optimizing the product shape

(Combining mold making and molding technologies to create a drawing proposal)

2) Rubber products that are more durable in cold weather

(Improving product characteristics through researching rubber composition)

3) Meeting specific requests

(Applying special techniques to improve specific functions)

Responding to a wide variety of customer requests, we are working to make improvements using our expertise.

* For confidentiality reasons, we are unable to provide more specific information.

Product: Self-service gas station equipment (case)

Requests: The case specifications were already fixed. We were asked to manufacture all of the rubber and plastic parts for the case.

Being asked to manufacture all of the rubber and plastic parts, we were able to achieve a smarter design. More precisely, we were able to reduce the number of components through integrating multiple components into one, improving the design and usability. Our redesigning based on the product concept succeeded in:

1) Reducing the number of components and cost through integrating multiple components into one

2) Improving the design

3) Improving the usability

* For confidentiality reasons, we are unable to provide more specific information.

* For confidentiality reasons, we are unable to provide more specific information.